High Efficiency Switch Welder

Solid State High Frequency Welder

PTJ High-Speed Electric Arc Spraying Machine

DFT - Direct Forming Technology

M.F Series

Spray Gun

Solid State HF Welder

Request Service Today

10

Years Experience of This Field

About Us

Metoweld Electro India Pvt. Ltd.

We M/s Metoweld Electro India Pvt. Ltd. are engaged in fulfilling the induction heating equipments requirement of the industry. We Specialize In Manufacturing High Frequency Solid State Welders, Online Seam Annealer.The equipment's are checked to meet the necessary quality standards before being dispatched. These equipments are sold by the brand name Metoweld.

Professional Team

Safety Assurance

SERVICES

Our Industrial Products

Why Choose us

Advantages Of Metoweld Electro India Pvt. Ltd.

There are many Solid State High Frequency Welder manufacturers in India. What distinguishes us from them is the customer centric approach we follow. We have always given priority to the needs of the customer. When pipe and tube manufacturers were looking for a cost efficient solution to replace aging vacuum tube welders, we realized the exact nature of their requirement and provided them with a reliable and cost efficiency solution.

OUR TEAM

CUSTOMER SATISFACTION

Our Services

We Provide Best

Industrial Products

- Solid State HF Welder

- High Efficiency Switch Welder

- PTJ High-Speed Electric Arc Spraying Machine

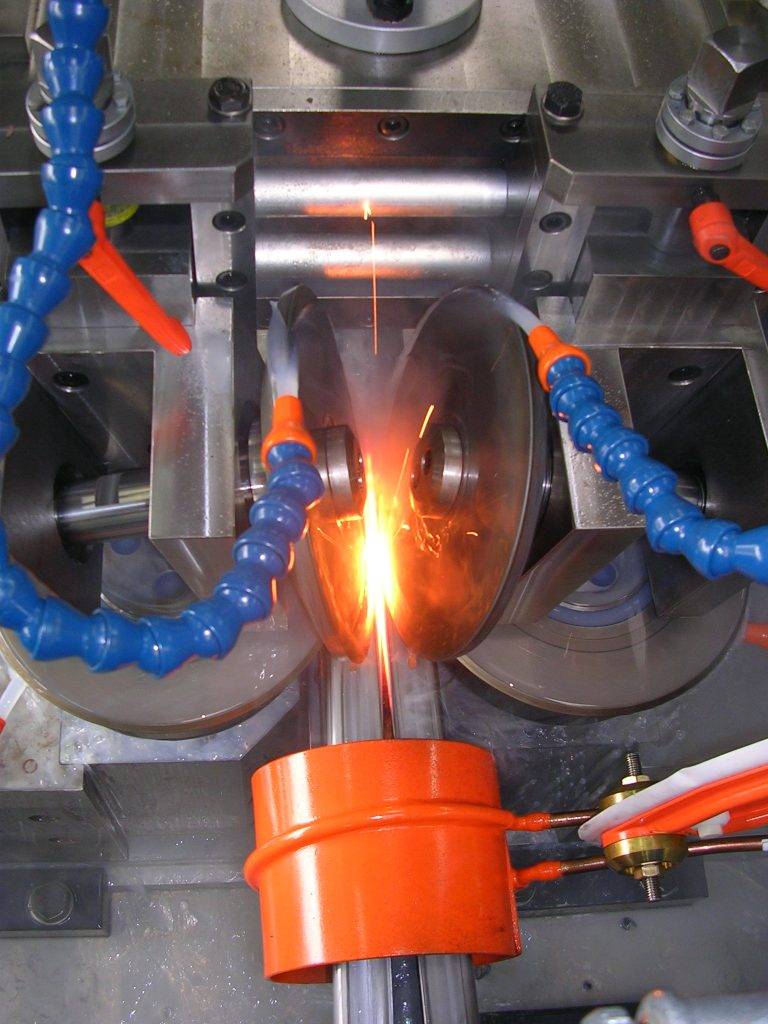

Solid State HF Welder

QGT-1 series solid state H.F. welder is specially designed for straight seam welding . It includes Inverter output unit, DC power unit, Central Control unit, Water-Water heat exchanger unit and Rectifier Isolation transformer.

Inverter Output Unit

The Inverter output unit is mainly made up by tank circuit capacitance C and the inductive coil Land uses MOSFET as the power device.

DC Power Unit

DC Power Unit includes 3‐phase full‐controllable thyristor rectifying bridge, flight wave reactor, flight wave capacitor

Central Control Unit

The tube mill line can be controlled from the central control unit. It also has meters for current and voltage measurement.

Rectifier Isolation Transformer

It steps down voltage from 415V to 200V and also isolates the welder from the power grid.

High Efficiency Switch Welder

High Efficiency : Comparing to traditional solid state welder, save power for 15%-25%.

Note: traditional solid state welder ripple coefficient is 4%, high efficiency switch welder is 2%.

Less installation cost

Welder room or elevated platform is necessary, all the cost will be about USD800-1600.

Solid State HF Welder

High-speed Electric Arc Spraying Machine developed by our company offers high efficiency, low energy consumption and high-tech product. It is based on the electric arc as heat source, melting the metal wire, atomization and cooling with the compressed air, making the metal wire into small particles, and then sprays to the surface of the work piece after heat treatment with high speed, in order to obtain the ideal coating. The spray gun adopts stepless speed regulation. It can spray on the metal wires with different melting point, such as zinc, aluminum, zinc alloy, copper, lead-tin alloy, high carbon steel, and stainless steel. The sprayed wire specification can be from 0 1.2 — 3.0 mm.

- Spray Gun Working Pressure/Consumption: 0.5Mpa / 1.85m3 /min

- Output Power: 16KW

- Output Current Max: 300A 400A 500A

Contact

Need Services Help?

Don't hesitate to call us for our Service, our team awaits your call.

Successful Projects

Satisfied Clients

Experienced Staff